Viston Education Teching Equipment

AI-Driven Collaborative Robotic Sorting Training Platform

AI-Driven Collaborative Robotic Sorting Training Platform

Couldn't load pickup availability

📌 Product Overview

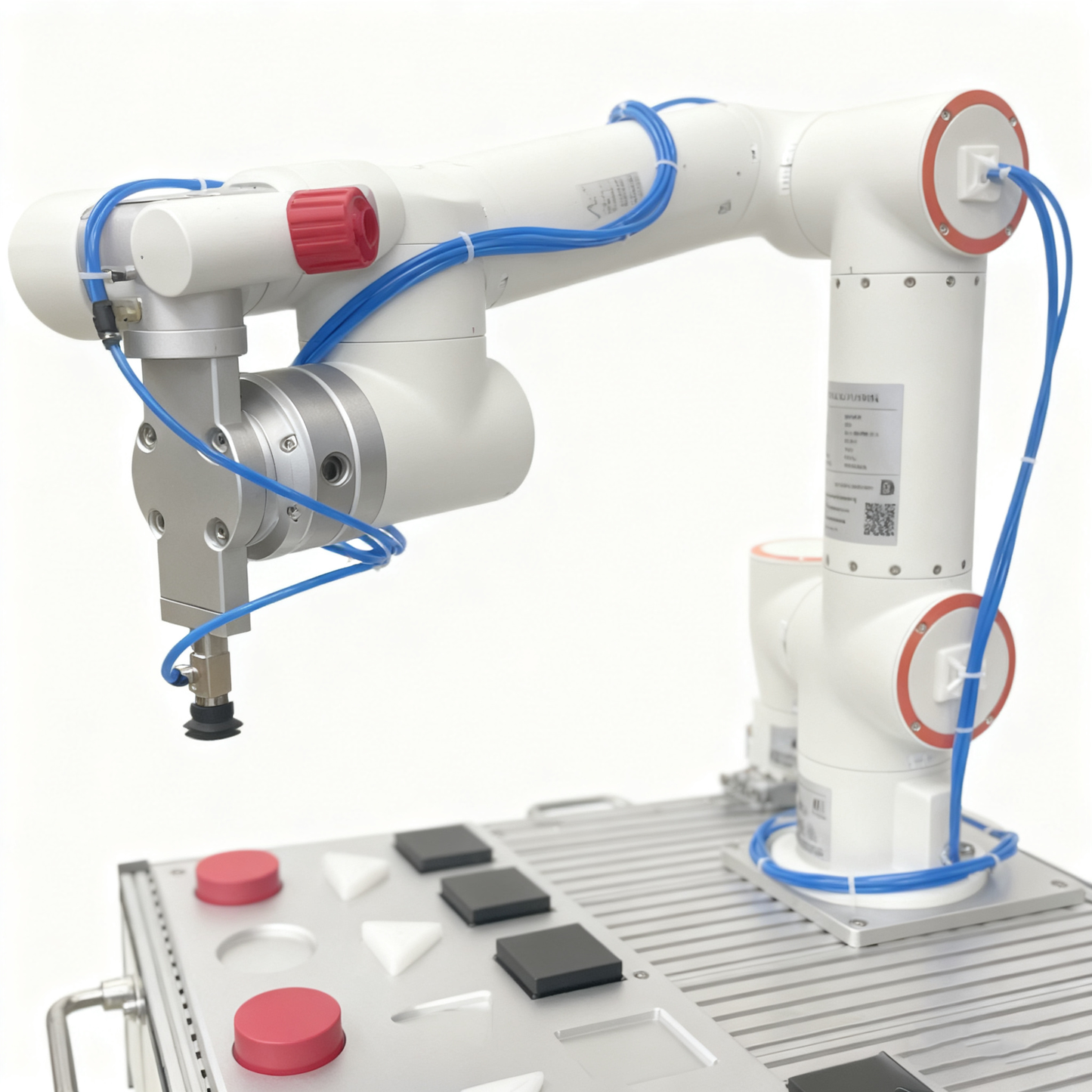

This advanced training platform is designed for vocational schools, technical colleges, and industrial training centers. It integrates a pneumatic-powered robotic arm with intelligent sorting capabilities, offering hands-on experience in mechatronics, automation, and collaborative robotics. With modular components and real-world simulation, it’s the perfect solution for cultivating next-generation talent in smart manufacturing.

🔧 Key Features

-

Intelligent Sorting System

Equipped with sensors and programmable logic to sort objects by color, shape, or material. -

Collaborative Robotic Arm

Simulates human-machine interaction in modern industrial environments, enhancing safety and flexibility. -

Pneumatic Control Module

Includes visible tubing and actuators for teaching pneumatic principles and troubleshooting. -

PLC Programming Interface

Compatible with major PLC brands (e.g., Siemens, Mitsubishi), allowing students to learn ladder logic and automation workflows. -

Sensor Integration

Features push buttons, photoelectric sensors, and emergency stop systems for interactive control and safety training. -

Modular Design

Easily reconfigurable for different training tasks, from basic pick-and-place to complex sorting operations.

🎓 Ideal For

- Mechatronics and robotics education

- Industrial automation training

- STEM labs and maker spaces

- Workforce development programs

- Smart factory demonstration setups

📦 Specifications

- Dimensions: 860mm × 540mm × 160mm

- Power Supply: AC 220V / 50Hz

- Materials: Aluminum alloy base with industrial-grade components

- Control System: PLC + manual interface + sensor triggers

- Accessories: Training manual, task modules, sample code, video tutorials

🚀 Educational Value

This platform empowers learners to master core skills in automation, robotics, and system integration. It bridges the gap between theory and practice, preparing students for careers in intelligent manufacturing and Industry 4.0.